Flexographic printing machine adopt sensitization resin as flexible printing plate, It is suitable for printing such packing materials as polyethylene,polypropylene bag,cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for good, supermarket handbag, vest bag and clothes bag,etc.

Performance:

Easy operation,flexible starting,accurate color register.

the meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

Pneumatic printing cylinder lift and lower, is will stir the printing ink automatically after lifting .

the printing ink is spread by the anilox cylinder with even ink color.

Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

360°continuous and adjustable longitudinal register device.

The frequency control of motor speed adapts to different printing speeds.

There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Flexo printing machine is used resin plate for printing texts and images on paper roll,plastic film roll,non woven roll,thermal paper roll etc. Both of water based ink and solvent ink can use.

|

|

YT-M6600 |

YT-M6800 |

YT-M61000 |

YT-M61200 |

|

Max.material width |

600mm |

800mm |

1000mm |

1200mm |

|

Max.printing width |

560mm |

760mm |

960mm |

1160mm |

|

Main motor power |

4kw |

4kw |

4kw |

4kw |

|

Total power |

27kw |

27kw |

28kw |

29kw |

|

Machine weight |

3300kgs |

3900kgs |

4400kgs |

4800kgs |

|

Outline dimension |

4.8x1.6x2.6m |

4.8x1.8x2.6m |

4.8x2.0x2.6m |

4.8x2.2x2.6m |

|

Printing colors |

6 colors (6+0,5+1,4+2,3+3) |

|||

|

Printing length |

220-1200mm |

|||

|

Machine speed |

100m/min |

|||

|

Printing speed |

70-80m/min |

|||

|

Material of Plate |

Resin or Rubber |

|||

|

Constitution of Printing |

Metal Anilox roller、Rubber roller 、Chrome plated roller、 printing Cylinder for printing length 400mm |

|||

|

|

Optional device :ceramic anilox roller,single doctor blade,ink pump; |

|||

|

Working Principle |

helical gears |

|||

|

Printing precision |

+/-0.25mm |

|||

|

Thickness of Plate (including the glue) |

2.38mm |

|||

|

Machine Voltage |

380V 50/60HZ 3PH |

|||

Loading container

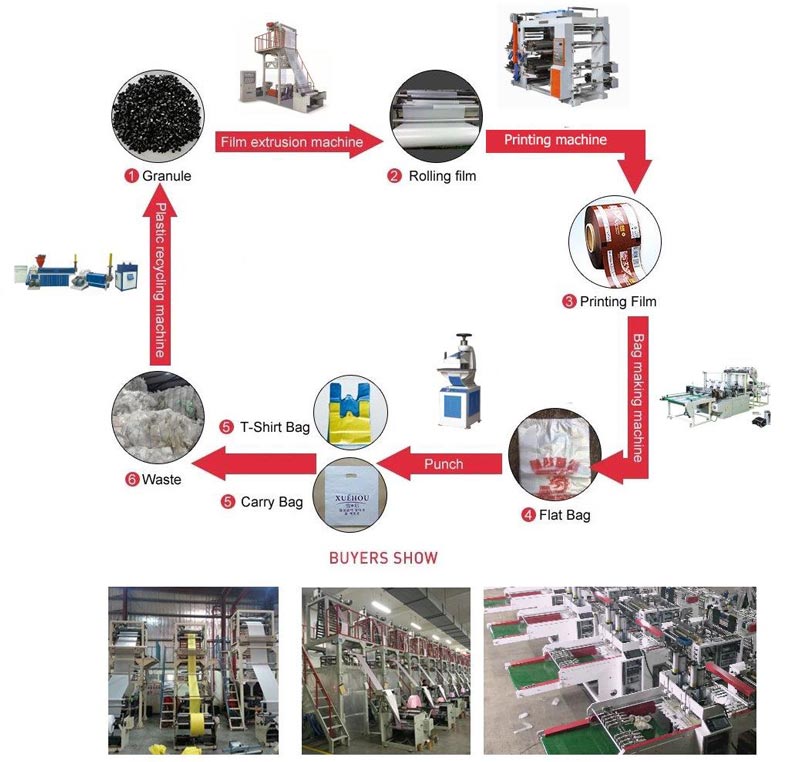

Kingdom Machine Co., Ltd. information column provides you with a film blowing machine, plastic bag machine, plastic recycling machine, flexo printing machine, stretch film machine, and bubble film machine information, including meaning, working principle, application fields, price, and other news.

This article tells you about the characteristics, application range, and maintenance methods of the film blowing machine so that you can understand it better and use it better.

The film blowing machine is used to blow HDPE and LDPE films, which are used in various high-end film packaging, plastic bag films, etc. This kind of film can be widely used in light and heavy packaging due to its good barrier properties, preservation, moisture-proof, frost-proof, oxygen-proof, and oil-resistant.

How to Build Up A Plastic T-shirt Bag Machine? Want Kind Of Machine Need To Buy?

Plastic films can be seen everywhere in our lives, but how did plastic films come from? We have to mention the blown film machine at this time.