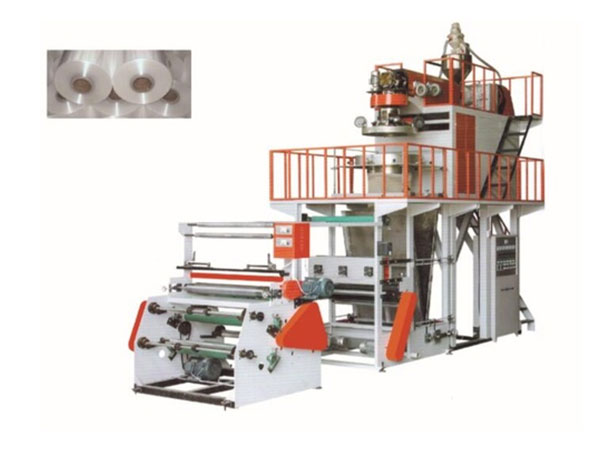

Film blowing machine knowledge: characteristics, application scope and maintenance methods of film blowing machine

Film blowing machine is a machine used to make plastic films. It works by squeezing and stretching molten plastic particles into a continuous film. This film can be used in packaging materials, plastic bags, agricultural covering films, construction films, and other fields. This article tells you about the characteristics, application range, and maintenance methods of the film blowing machine so that you can understand it better and use it better.

Features of film blowing machine

1. The screw and barrel are made of alloy steel, which has been nitrided and precision machined. It has high hardness, strong corrosion resistance, and durability;

2. The screw has a large length-to-diameter ratio, strong plasticizing ability, and uniform temperature distribution, and the die head is plated with hard chromium. Its structure is a spiral mandrel. The extruded molten material is uniform, and the blown film is bright and uniform. The product has good performance;

3. The winding device adopts a torque motor, which can maintain appropriate tension, make the winding neat and easy to change the roll;

4. Adopt advanced frequency conversion technology, high efficiency, and energy saving;

5. The rotating film head can be configured according to user needs.

The film blowing machine is simple to operate has high production efficiency, and is widely used in the plastic processing industry.

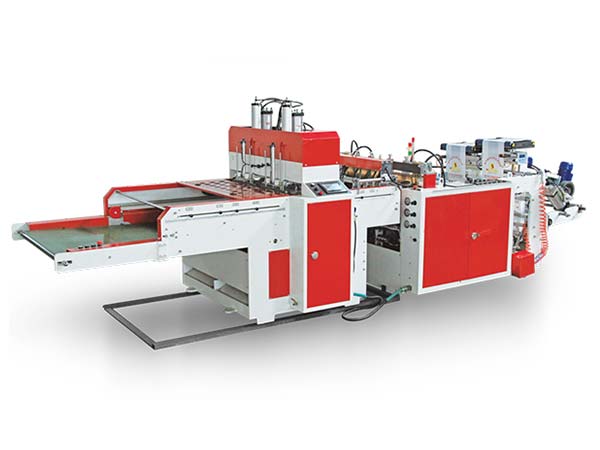

Application scope of film blowing machine

The plastic film produced by the film blowing machine is widely used in many fields depending on the materials and characteristics. Suitable for various high-end film packaging, plastic bag films, protective films, etc. Because of its good barrier properties, preservation, moisture-proof, frost-proof, oxygen-insulating, and oil-resistant, it can be widely used in light and heavy packaging. Such as various fresh fruits, meat products, pickles, fresh milk, liquid drinks, medical supplies, etc.

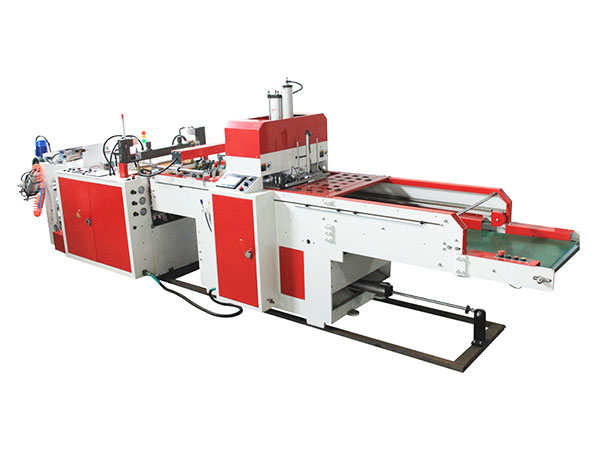

Commonly used maintenance methods for plastic film blowing machines

1. Place the sealing machine in a ventilated and dry place to maintain the appropriate working temperature of the machine.

2. Every few days of operation, the machine parts should be lubricated.

3. Dust removal should be done regularly to keep the overall machine clean. Unplug the power source when not in use, cover it with a cloth, and do a good job of dustproofing it.

4. If the machine is running for a long time, the cooling fan should be turned on before shutting down and then shut down after the temperature drops. If the machine is shut down without cooling, the high-temperature belt will be easily damaged.

5. The high-temperature belt should be regularly cleaned of dust to ensure sealing quality.

6. Seriously worn parts should be replaced in time to extend the life of the whole machine, otherwise, the operating efficiency of the machine will be affected.

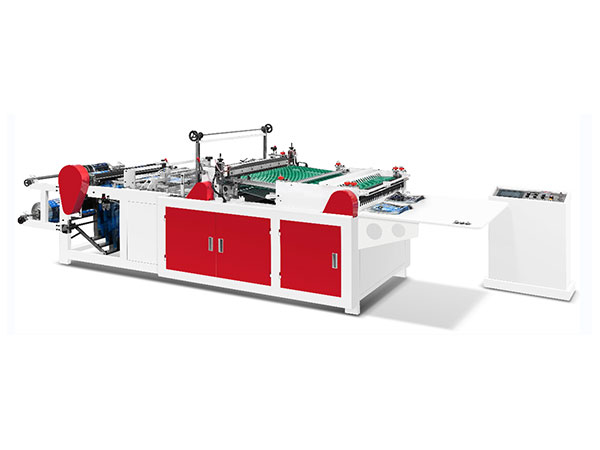

Expand knowledge: Types of PE film blowing machines

Single-screw film blowing machine, ABA film blowing machine, twin-screw film blowing machine, three-layer co-extrusion film blowing machine, five-layer co-extrusion film blowing machine

The purpose of each type of film blowing machine is different. Choose according to the products you make. This kind of equipment is suitable for you. It does not mean that the larger the model and the higher the configuration, the film blowing machine is the best. Each product uses The equipment is also different.

For example, ABA film blowing machine: This type of film blowing machine is suitable for making films with fillers in the middle layer, which can further save costs and improve the quality of PE films.

To comply with social product needs and environmental protection needs, plastic film blowing machines will gradually introduce new technologies and adjust the industrial model. In the future, as technology continues to deepen, film blowing machines will play more roles through continuous upgrading and promote the plastics and packaging industry to move towards the high end.