The purpose of the film blowing machine and the solution why the film blowing machine does not discharge material

The film-blowing machine equipment manufacturer tells you what the film-blowing machine is used for, the reasons why the film-blowing machine does not discharge material, and the solutions

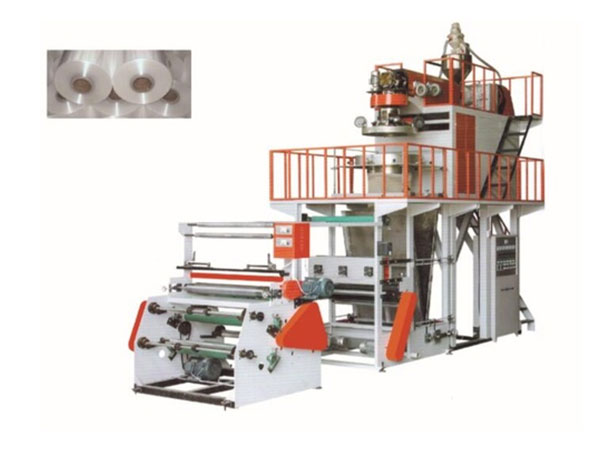

What is the film blowing machine used for?

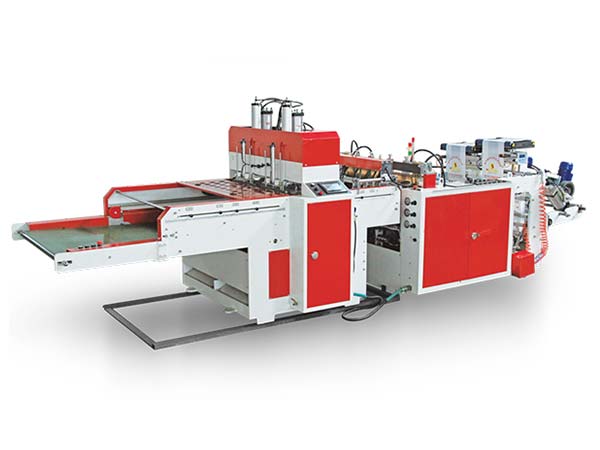

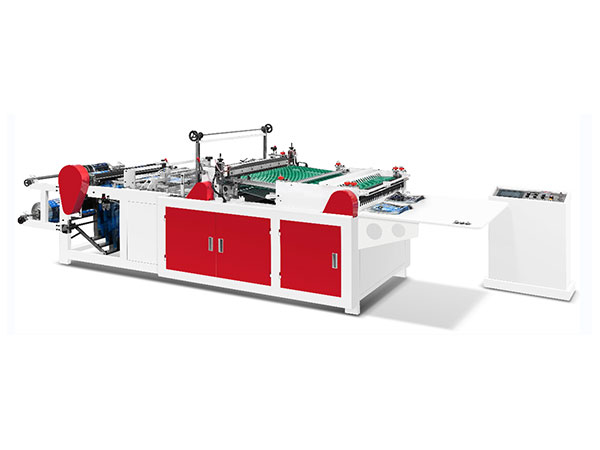

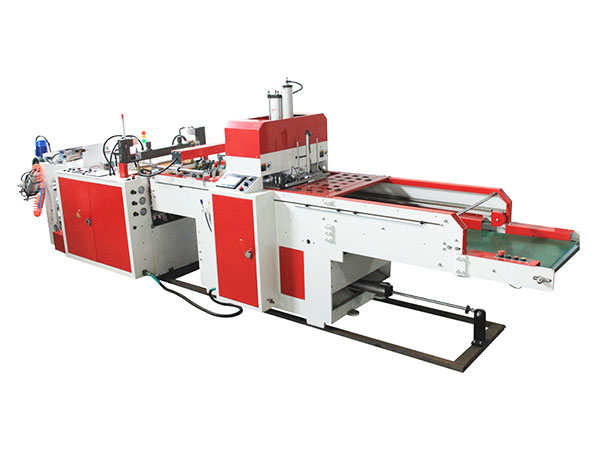

The film blowing machine is used to blow HDPE and LDPE films, which are used in various high-end film packaging, plastic bag films, etc. This kind of film can be widely used in light and heavy packaging due to its good barrier properties, preservation, moisture-proof, frost-proof, oxygen-proof, and oil-resistant.

The film-blowing machine is mainly composed of a motor, gearbox, screw, mold, frame, rewinder, power distribution cabinet, and other structures.

Motor: Generally, a soft connection or hard connection is used to provide power for the equipment.

Gearbox: Provides torque to the screw and uses a rigid connection.

Screw: Molten plastic particles are squeezed into a mold.

Mold: Blow molding, divided into high-pressure and low-pressure molds.

Frame: Provides movable operating stations and is the carrier of a series of mechanical parts such as upper traction, bubble stabilizing rack, and edge inserter.

Rewinding: Rewinding and shaping, are divided into double rewinding, single rewinding, automatic and manual.

What are the reasons and solutions for the film-blowing machine not discharging material?

1. The barrel screw feed port is severely worn. The raw materials only tumble at the feed port but lack the power to push forward. The barrel screw needs to be replaced.

2. The temperature of the feed port is extremely high, and the raw materials have begun to plasticize before entering the barrel. The plasticized raw materials stick to the screw groove of the feed port, blocking the entrance (commonly known as holding the rod). It is necessary to clean the barrel screw after stopping the machine and lower the temperature of the feed port before starting the machine again.

3. The temperature of the die head is too low, and the material becomes hard and blocks the extrusion channel. This phenomenon should be avoided as much as possible, otherwise, it will easily cause major accidents such as tee cracking and screw twisting.

Film-blowing machine application areas

1. Packaging industry:

Film-blowing machines are widely used in the plastic packaging industry and can produce various plastic films, such as polyethylene films, polypropylene films, etc., for making plastic.

Bags, plastic packaging films, and other products.

2. Agricultural field:

The film-blowing machine can produce agricultural films, such as agricultural covering films, greenhouse films, etc., which are used for agricultural production such as farmland covering and greenhouse planting.

3. Construction industry:

Film-blowing machines can produce architectural films, such as waterproof films, thermal insulation films, etc., which are used for waterproofing, heat insulation, and other applications in construction projects.

4. Medical and health care:

The film-blowing machine can produce medical films, such as medical surgical films, packaging films, etc.