Plastic Rolling T-shirt Bag Machine uses step motor or servo motor for feeding, machine speed control by computer. Bag machine easy to change bag size by computer. Plastic rolling bag machine is specialized for manufacturing perforated core-less bag on roll bag and rolling bag with core.

Features

Main Technical Variables:

|

Model |

KDB-500H |

|

bag making speed |

30-190pcs/min |

|

Length of bag making |

100-1200mm |

|

Width of bag making |

60-300mm |

|

Thickness of bag making |

0.005-0.015mm |

|

Bag making methods |

Flat open bag with core |

|

Material feeding |

AC motor with inverter control |

|

Bag length control |

Servo motor ,China brand 3kw |

|

Main motor |

1.5kw with inverter control |

|

Heating power |

2kw |

|

Total power |

8kw |

|

Machine size |

6000*1300*1800mm |

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

Kingdom Machine Co., Ltd. information column provides you with a film blowing machine, plastic bag machine, plastic recycling machine, flexo printing machine, stretch film machine, and bubble film machine information, including meaning, working principle, application fields, price, and other news.

This article tells you about the characteristics, application range, and maintenance methods of the film blowing machine so that you can understand it better and use it better.

The film blowing machine is used to blow HDPE and LDPE films, which are used in various high-end film packaging, plastic bag films, etc. This kind of film can be widely used in light and heavy packaging due to its good barrier properties, preservation, moisture-proof, frost-proof, oxygen-proof, and oil-resistant.

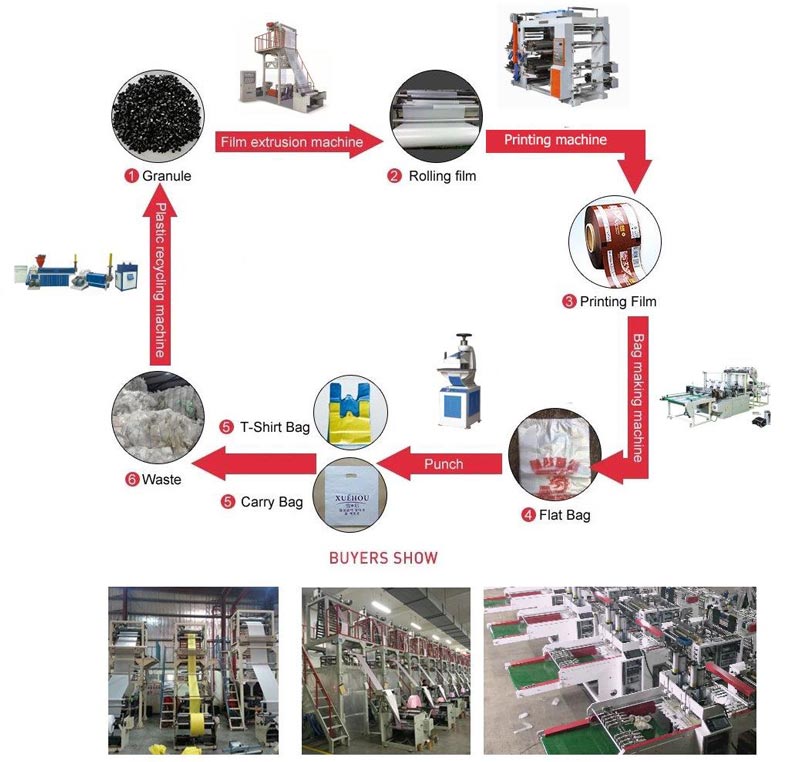

How to Build Up A Plastic T-shirt Bag Machine? Want Kind Of Machine Need To Buy?

Plastic films can be seen everywhere in our lives, but how did plastic films come from? We have to mention the blown film machine at this time.