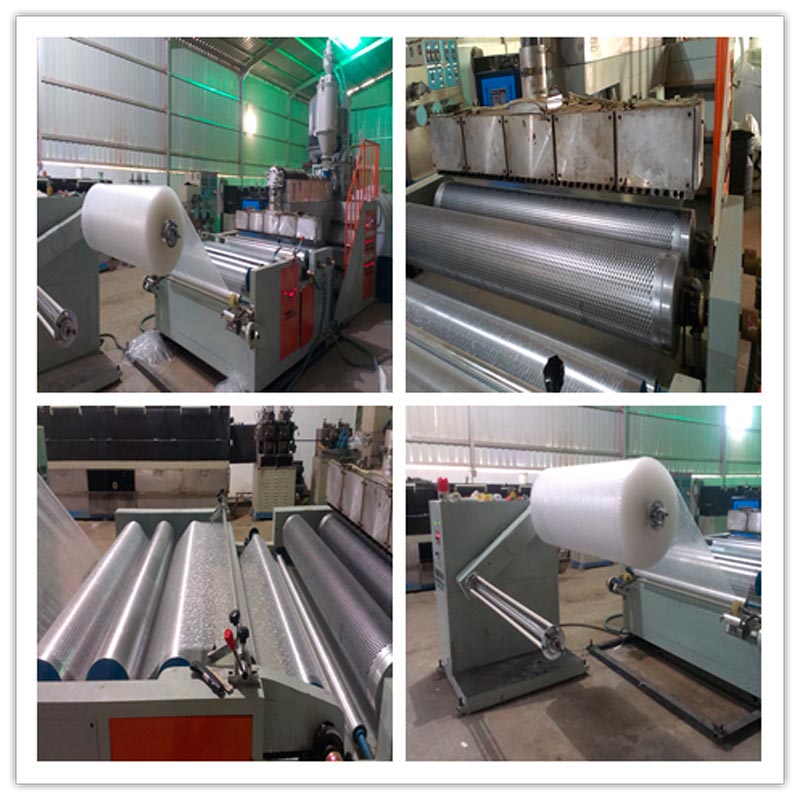

Two layers air bubble film machine also called air bubble wrap film extrusion, machine use Low Density Polyethylene (LDPE) produce air bubble film. Air bubble film machine simple design,easy operate,design for 24 hours 7 days working.

A two-layer air bubble film machine is a type of manufacturing equipment used to produce air bubble film, also known as bubble wrap. This machine is designed to create two layers of film with air bubbles sandwiched between them, providing added protection and cushioning for items during shipping and storage.

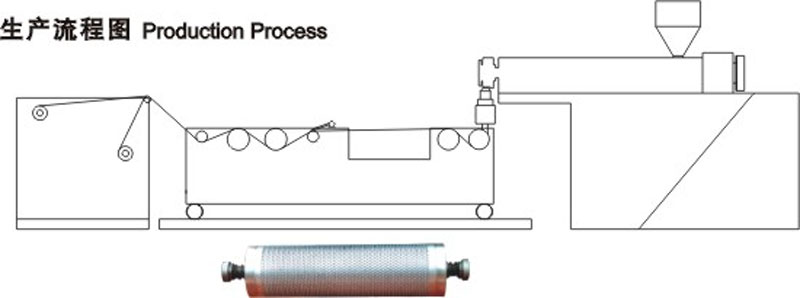

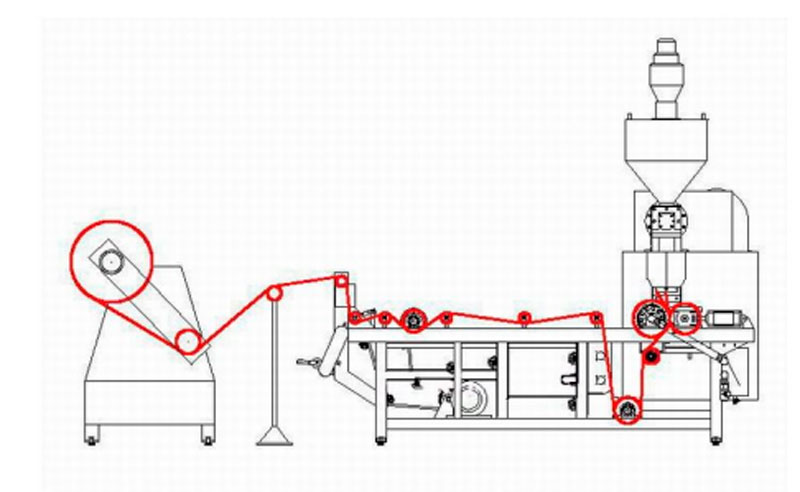

A two-layer air bubble film machine works by extruding two layers of plastic film, usually made from materials like polyethylene, and then using a special process to trap air between the two layers, creating the characteristic bubbles. The two layers are then laminated together to form a single sheet of air bubble film.

|

Model |

KDPE-1000 |

KDPE-1200 |

KDPE-1500 |

|

Raw Material |

LDPE |

LDPE |

LDPE |

|

Screw Diameter |

φ65mm |

φ75mm |

φ90mm |

|

Film Width |

1000mm |

1200mm |

1500mm |

|

Film Layer |

Two Layers |

Two Layers |

Two Layers |

|

Bubble Hole Diameter(mm) |

6,8,10,12,14,16,18,20mm |

||

|

Film Color |

Transparent,Black,Red,White,blue…bag color changed by masterbatch |

||

|

Output |

50kg/h |

60kg/h |

70kg/h |

|

Total Power |

48kw |

58kw |

68kw |

|

L/D Ratio Of Screw |

28:1 |

28:1 |

28:1 |

|

Water Consumption |

0.5m3/h |

0.5m3/h |

0.5m3/h |

|

Machine Weight |

3 |

4 |

5 |

|

Power Voltage |

220V,380V,440V |

||

|

Air Shaft Diamater |

without paper core ,58mm,76mm |

||

|

Machine Working Time |

24 hours*7 |

24 hours*7 |

24 hours*7 |

|

Warranty |

1 year |

||

|

Technical Assistance |

Engineers available to service machinery overseas |

||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Our Main parts cooperator as following brand,but standard parts all made from China.

These machines are often used by packaging and shipping companies, as well as manufacturers who need to protect their products during transit. The two-layer design provides extra strength and durability, making the air bubble film suitable for a wide range of applications.

Overall, a two-layer air bubble film machine is an essential piece of equipment for producing high-quality protective packaging materials, and it plays a crucial role in ensuring that items are safely and securely packaged for shipping.

Tags:Two Layers Air Bubble Film Machine,Bubble Film Making Machine,2 Layer Air Bubble Film Machine,Double Layer Air Bubble Film Machine

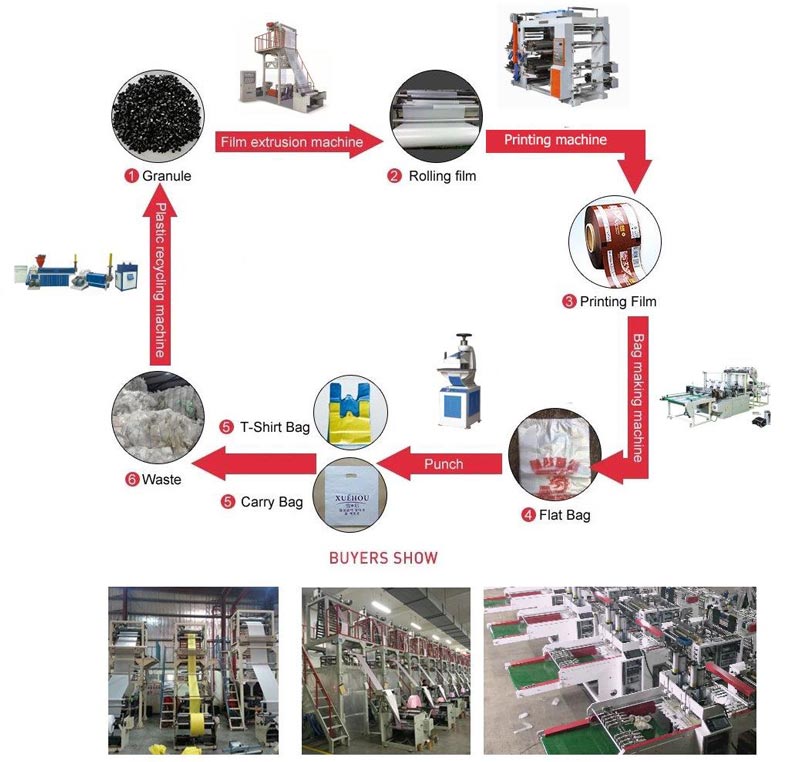

Kingdom Machine Co., Ltd. information column provides you with a film blowing machine, plastic bag machine, plastic recycling machine, flexo printing machine, stretch film machine, and bubble film machine information, including meaning, working principle, application fields, price, and other news.

This article tells you about the characteristics, application range, and maintenance methods of the film blowing machine so that you can understand it better and use it better.

The film blowing machine is used to blow HDPE and LDPE films, which are used in various high-end film packaging, plastic bag films, etc. This kind of film can be widely used in light and heavy packaging due to its good barrier properties, preservation, moisture-proof, frost-proof, oxygen-proof, and oil-resistant.

How to Build Up A Plastic T-shirt Bag Machine? Want Kind Of Machine Need To Buy?

Plastic films can be seen everywhere in our lives, but how did plastic films come from? We have to mention the blown film machine at this time.